Top Short-Term Job Oriented Courses After B.Tech Mechanical Engineering

SIPL is One of The Best Training Institute in Lucknow which provides Basic 2 Advanced Course Details, Duration, Fees, Location & Certification

Top Short-Term Job Oriented Courses After B.Tech Mechanical Engineering:

1. HVAC (Heating, Ventilation & Air Conditioning)

- HVAC stands for Heating, Ventilation, and Air Conditioning. It is a process of treating the air to control its temperature, and humidity, filtering and distributing it to meet the comfort requirements of the occupant or people in the conditioned space (room).

- By using HVAC, we can control the temperature, humidity, filtration, and airflow. HVAC can be used in houses and villas (Residential), offices (commercial), hospitals and pharmaceuticals, Malls and theaters, Industries, Educational institutes (Schools, Colleges, Classes), and various other places( Aircrafts, etc).

Major Components of HVAC system

- Compressor: It is known as the heart of the HVAC system which pumps refrigerant into the system. It separates the high-pressure system from the low-pressure system. If the compressor fails, there will be no cooling.

- Condenser: It has coils that help to get rid of the heat from the space or room. It can be of two types, namely, the Air-cooled type (located outside, in the open) or Water cooled type(located inside, cooled with a cooling tower).

- Evaporator: It provides cool air into the room. This is located after the air filter. It helps in removing moisture from the refrigerant (air/water). As it filters dirt and dust from refrigerant (air/water), requires periodic maintenance.

- Fan: The fan helps to intake fresh or ambient air from the atmosphere and helps to mix it across the evaporator coil. It is in front of or behind the evaporator coil.

Future Scope of HVAC System:

HVAC systems of the future will use technologies such as more geothermal heat pumps, solar power, smart thermostats, and even ice-powered air-conditioning to reduce their energy use and overall environmental impact.

2. Automotive Part Design Courses:

- Automotive design is the process of developing the appearance (and to some extent the ergonomics) of motor vehicles - including automobiles, motorcycles, trucks, buses, coaches, and vans.

- The functional design and development of a modern motor vehicle are typically done by a large team from many different disciplines also included within automotive engineering, however, design roles are not associated with requirements for professional- or chartered-engineer qualifications.

Automobile Interiors: The designer responsible for the vehicles' interior develops the proportions, shape, placement, and surfaces for the instrument panel, seats, door trim panels, headliner, pillar trims, etc. The procedure here is the same as with exterior design (sketch, digital model, and clay model).

Exterior Plastic Parts in Automotive: The design team(s) responsible for the exterior of the vehicle develops the proportions, shape, and surface details of the vehicle. Progressively, drawings that are more detailed are executed and approved by appropriate layers of management, followed by digital rendering of images.

Seating System in Automotive: In Automobiles, the Seat is a very important part. The standard car seat is designed to support the thighs, the buttocks, lower and upper back, and head support. When choosing this product, foam manufacturers must consider the most suitable foam for balancing comfort, support, safety, and recycling properties.

Scope of Automobile Industry in India

The automobile industry is a massive industry and one of the most important goods in everyone’s life because work is impossible without transportation. Automobile Engineering is one of the most complex engineering courses, involving the design, manufacture, administration, and investigation of automobiles during repairs, rebuilding, and modification. It entails the design of automobiles such as cars, bus routes, Lorries, and other types of vehicles used for road travel.

Companies: ADIENT, Farrecia, MAGNA, and CEAR are the top companies for part designing of Automobiles.

3. Piping Design

- The basic concept of a geothermal piping design is to safely and economically transport steam, brine, or two-phase flow to the destination with acceptable pressure loss. The piping associated with the geothermal power plant can be divided into piping inside the power plant and the piping in the steam field.

- The design process consists of the establishment of the design criteria for the piping system- For a proper piping design, it is essential that the client and the contractor agree on a design basis, process, mechanical, civil, and electrical control, and instrumentation.

Design procedure: The problem of the design procedure is to find a pipeline configuration and size within the constraints, which is safe and economical.

Fluid characteristic: Important factors to be considered are the mass flow rate, pressure, temperature, saturation index, and allowable head loss over the pipeline length.

Separator location: The separator location is controlled by site topography, process and control system requirements, and the pipes.

Pipe types and applications:

- Seamless pipe (SMLS): These pipes are extruded and have no longitudinal seam. There is no weld and is the strongest of the three types of pipes mentioned.

- Submerged arc welded pipe (SAW): These pipes are manufactured from plates, normally rolled and seam welded together. The welding has a joint efficiency of 0.95.

- Electric resistance welded pipe (ERW): These pipes are manufactured from plates, where the seam weld is done by electric resistance welding. The welding efficiency is 0.8.

Design codes: The principal design codes used for piping design are the ANSI/ASME B31.1 (Code for Power Piping) and ANSI/ASME B31.3 (Code for Process Piping).

Pipe routes: Using the preliminary pipe route, an estimate of equivalent line length can be made. The design flow and enthalpy are determined from the good data, and with this information, the optimum diameter for the pipes can be known. Figure 3 shows a contour plan of the Berlín geothermal field.

Structural analysis: Circumferential stress or Hoop stress due to pressure and vacuum is considered for sizing and selecting the pipe with suitable wall thickness.

Future Scope in Pipe Designing:

Piping engineering has good job opportunities all over the world. Chemical process plants, Refineries, and Power Plants use a lot of piping. Engineering companies such as Bechtel, Fluor, and J Ray McDermott are always on the lookout for good mechanical engineers to become piping engineers.

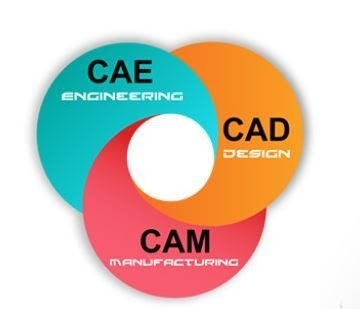

4. CAD/CAM/CAE Courses:

CAD: CAD (computer-aided design) is the use of computer-based software to aid in design processes. CAD software is frequently used by different types of engineers and designers. CAD software can be used to create two-dimensional (2-D) drawings or three-dimensional (3-D) models.

Examples of CAD software: AutoCAD, CATIA, Fusion 360, NX, SolidWorks, etc.

CAM: Computer-Aided Manufacturing (CAM) is the use of computer software to control machine tools in the manufacturing of modules. CAM transforms engineering designs into end products. 03. Computer-Aided Design is also known as Computer-Aided Drafting. Computer-Aided Manufacturing is also known as Computer-Aided Modeling.

CAE: Computer-aided engineering refers to the use of software to simulate the effects of different conditions on the design of a product or structure using simulated loads and constraints. CAE tools are often used to analyze and optimize the designs created within CAD software. Major categories of CAE tools include finite element analysis (FEA), computational fluid dynamics (CFD), and multidisciplinary design optimization (MDO). These tools are used to perform design iterations using virtual prototypes (sometimes called “digital twins”) prior to building physical prototypes. This saves companies significant time and money in product development while often yielding higher-quality designs that meet multi-disciplinary and multi-functional requirements.

Future Scope of CAD /CAM Engineers:

Tech CAD/CAM scope is very flexible and has a wide spectrum of exciting employability opportunities in a wide variety of sectors some of the popular roles that the graduates start with are: Design Engineering, Senior Mechanical Engineer, Software Engineer.

5. Tool Designing:

Tool design is a specialized area of manufacturing engineering comprising the analysis, planning, design, construction, and application of tools, methods, and procedures necessary to increase manufacturing productivity. To carry out these responsibilities, tool designers must have a working knowledge of machine shop practices, tool-making procedures, machine tool design, and manufacturing procedures and methods, as well as the more conventional engineering disciplines of planning, designing, engineering graphics, and drawing, and cost analysis.

Design objectives

- Reduce the overall cost to manufacture a product by making acceptable parts at the lowest cost.

- Increase the production rate by designing tools to produce parts as quickly as possible.

- Maintain quality by designing tools to consistently produce parts with the required precision.

- Reduce the cost of special tooling by making every design as cost-effective and efficient as possible.

- Design tools to be safe and easy to operate.

Tool designer responsibilities

- Cutting tools, tool holders, and cutting fluids;

- Machine tools, including modified or special types;

- Jigs and fixtures;

- Gages and measuring instruments;

- Dies for sheet metal cutting and forming;

- Dies for forging, upsetting, cold finishing, extrusion, and

- Fixtures and accessories for welding, riveting, and another mechanical fastening.

Future Scope of Tool Designer:

The scope of tool designing is definitely on the rise in and out of India. Experience matters a lot in this profession and the same offers a lucrative salary for aspirants. An average tool engineer can get up to Rs. 2.25 lakh rupees annually.

What's Your Reaction?

![List of Top SAP Training Institutes in India: 2025 [Updated]](https://www.sipltraining.com/blog/uploads/images/202302/image_100x75_63e4b203cb050.jpg)

![10 Best SAP Training Institutes in India with Placement 2025 [Updated]](https://www.sipltraining.com/blog/uploads/images/202301/image_100x75_63c50aa3de731.jpg)